Journal of the Ceramic Society of Japan

vol. 132, no.5, 2024

◆Full papers◆

Temperature-strain rate-dependent flow stress model of ceramic materials

https://doi.org/10.2109/jcersj2.23199

https://doi.org/10.2109/jcersj2.23199

Hai Bo Kou, Yao Wen Gao, Jia Xing Shao, Kai Yue Dou and Jian Zhang

197

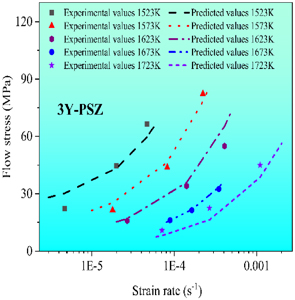

Flow stress is one of the most significant plastic mechanical properties of ceramic material at high temperature, and it is crucial to its processing and manufacturing. In the present paper, a novel temperature-dependent flow stress model for ceramic materials is proposed firstly. The model establishes a clear and meaningful relationship between the flow stress and various material parameters including temperature, elastic modulus, Poisson’s ratio, melting point, and particularly, without any fitting parameters. Then, the individual effect of strain rate and the coupling effect of temperature and strain rate on flow stress is investigated. In this way, a new temperature-strain rate-dependent flow stress model for ceramic material is developed. And the model is verified by comparison between its predicted data and the available experimental results of different ceramic materials. So that the variation law of flow stress with temperature and strain rate can be well described by the presented model. In addition, compared with traditional models, the presented model has simpler form, clearer mechanism and fewer fitting parameters. Achievements of this paper can provide a foundation for the service stability and safety evaluation of ceramic materials.

Corrosion behavior of calcium-magnesium-alumino-silicate on (La,Gd)2Zr2O7/YSZ multilayer for thermal barrier coatings

https://doi.org/10.2109/jcersj2.23096

https://doi.org/10.2109/jcersj2.23096

Seung-Hyeon Kim, Toshio Osada, Kee-Sung Lee, Yoon-Suk Oh, Nobuo Nagashima and Byung-Koog Jang

205

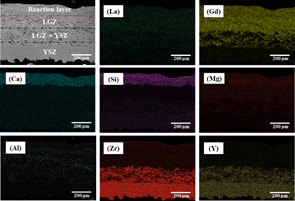

In this study, the high-temperature corrosion behavior was evaluated for (La,Gd)2Zr2O7 (LGZ) used as a promising thermal barrier coatings (TBCs) material. (La,Gd)2Zr2O7 + YSZ multilayer prepared from atmospheric plasma spray (APS) were exposed to calcium-magnesium-alumino-silicate (CMAS) melt at 1300 °C for 2, 12, 48, and 100 h. Molten CMAS and (La,Gd)2Zr2O7 reacted to form reaction layer Ca2Gd8(SiO4)6O2 (apatite) at 1300 °C. The thickness of the reaction layer increased with increasing heat-treatment time. A correlation between the hardness and Young’s modulus relationship for the reaction layer of the coating was observed for the microstructure using nanoindentation. It was confirmed that the pores of the coating were reduced through the infiltration of molten CMAS in the initial stage of the corrosion reaction, and the hardness and Young’s modulus were increased due to densification. Fracture toughness increased with heat treatment time in both directions (in-plane and through-thickness). The fracture toughness in the in-plane direction is 0.19–0.23 MPa\sqrtm . On the other hand, the fracture resistance in the thickness direction was 0.87–1.26 MPa\sqrtm , which was higher than that in the in-plane direction. These results show that the crack propagates in the in-plane direction and causes TBC delamination.

Phase-field simulation of vapor pressure for micropore formation in pseudo-binary system, B2O3–UO2

https://doi.org/10.2109/jcersj2.23183

https://doi.org/10.2109/jcersj2.23183

Munemichi Kawaguchi, Sota Hamajima and Masayoshi Uno

214

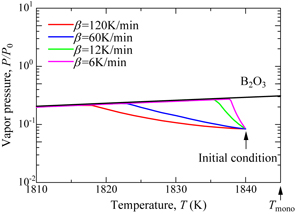

We performed thermodynamic and phase-field (PF) simulations to investigate micropore formation mechanisms in a pseudo-binary system, B2O3–UO2, during the solidification process. In the B2O3–UO2, a solid UO2 nucleation occurs in liquids below the melting point (Tm). As the temperature decreases further, a monotectic reaction (Liquid → S + Liquid#2) occurs below the monotectic temperature (Tmono ≈ 1845 K). Here, S and Liquid#2 denote the phases of solid UO2 and second liquid containing low UO2 concentration. This study calculated that the behaviors of the Liquid and S phases during the cooling process depended strongly on the cooling rates, leading to high vapor pressure of the liquid phase due to the low UO2 concentration. The vapor pressure of liquid phase showed comparatively high values at high temperatures. In this PF simulation, the UO2 concentration of the liquid phase decreased rapidly at 1838 K under a low cooling rate (β = 6 K/min). Therefore, the porosity was considered to increase by vaporization of the liquid. On the other hand, under a high cooling rate (β = 120 K/min), the porosity could be lower than under the low cooling rate condition because the UO2 concentration decreased at lower temperature. The dependency between porosity and a cooling rate is consistent with Yusufu’s experimental results.

Fabrication and electrical characteristics of fine-grained ZnO varistors with crystal orientation for multilayer ceramic devices

https://doi.org/10.2109/jcersj2.23124

https://doi.org/10.2109/jcersj2.23124

Yoshiko Higashi and Eiichi Koga

222

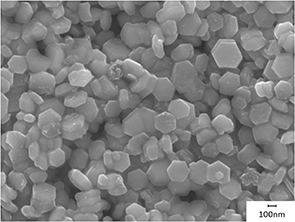

ZnO varistors are able to be successfully fabricated containing c-axis oriented fine grains of 2.5–2.8 µm for the first time, by using fine hexagonal templated ZnO. The crystalline orientation is clarified to have significant effects on the electrical behaviors of grain boundaries, even with low orientational degree (e.g., as Lotgering factor of 0.116). Break down voltage per a grain boundary (Vgb) and εr decrease by 16 and 5 % in perpendicular direction to the c-axis alignment from those in parallel, respectively. The control of crystal orientation has a possibility of leading to further advance in protection performance of ZnO-based multilayer varistors.

Effect of Si addition on epitaxial growth and gas sensing properties of tungsten oxide films

https://doi.org/10.2109/jcersj2.23121

https://doi.org/10.2109/jcersj2.23121

Yutaka Adachi

227

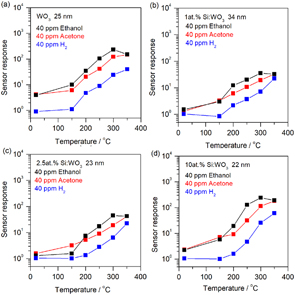

WO3 epitaxial films with the same thickness and in-plane crystal grain size were prepared using pulsed laser deposition with various Si contents in the target to clarify the effect of Si addition to WO3 on the gas sensing properties. X-ray diffraction measurements indicated that the films grown on the (1−102) face of sapphire had a (001) orientation with in-plane epitaxial relationships of [110]WO3//[01−11] or [110]WO3//[2−110]Al2O3, regardless of the Si content. Scanning probe microscopy observations revealed that particles with a diameter of several tens of nanometers grow on the surface of the Si-doped WO3 film. Measurements of the gas response to ethanol and acetone showed superior gas selectivity towards acetone gas at low temperatures, which is due to the catalytic effect of SiOx particles on the film surface.

Effect of monomer structure on carbonization process of gel-cast green body and electrical property of sintered body

https://doi.org/10.2109/jcersj2.23174

https://doi.org/10.2109/jcersj2.23174

Yoshiaki Funahashi, Yunzi Xin, Kunihiko Kato and Takashi Shirai

232

In this study, the gel-cast green bodies of alumina/graphite composites were fabricated using various epoxy monomers. The effects of the molecular structure of the monomers on the carbonization behavior and electrical conductivity of the reductively sintered bodies were systemically investigated. In the case of carbonization behavior under a temperature range of 300–700 °C, the amount of ether group in epoxy monomers exhibited influence on carbon residue amount. Moreover, carbonization of the multifunctional epoxy monomer induced fewer defects in the carbon network than carbonization of the bifunctional monomer. In addition, the graphitization characteristics of sintered bodies under 1600 °C correlated well with carbonization process. The relationship between carbonization/graphitization and the electrical properties of the sintered bodies is discussed in this paper.

Aqueous synthesis of dark copper oxide selectively reflecting near-infrared rays

https://doi.org/10.2109/jcersj2.23171

https://doi.org/10.2109/jcersj2.23171

Yuichi Kobayashi, Jun’ichi Kawano, Yuh Kato, Kohei Fukushima, Kyoka Ohashi, Runa Ohtani and Tomoya Osawa

238

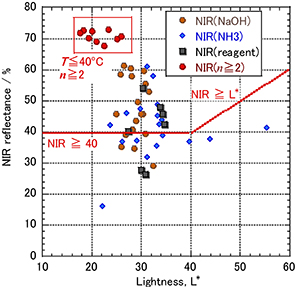

Blue copper hydroxide was synthesized by adding aqueous ammonia or sodium hydroxide to copper chloride, copper nitrate, and copper sulfate solutions, and black copper oxide was produced by heat treatment after filtration. When excess sodium hydroxide was added to copper chloride, copper nitrate, and copper sulfate solutions, the precipitated blue copper hydroxide changed to black copper oxide over time. The effects of synthesis temperature, synthesis time, and excess sodium hydroxide on the spectral reflectance of the precipitated copper oxide in the visible and near-infrared regions were determined. Under optimum conditions, it was possible to synthesize black copper oxide (II) with a visible light region reflectance of less than 5 % and a near-infrared region reflectance of more than 70 %. This copper oxide can be applied to high solar reflective paints necessary for heat island measures.

Effect of Si content on the phase transformation and pore structure evolution of porous Mo–Al–Si–B ceramics

https://doi.org/10.2109/jcersj2.23160

https://doi.org/10.2109/jcersj2.23160

Zhensen Yu, ZhanWen He and Junsheng Yang

245

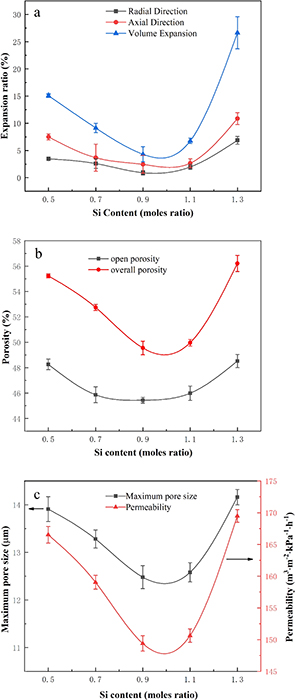

Porous Mo–Al–Si–B ceramics were prepared by activation reaction sintering method utilizing Mo, Al, Si and B elemental particles as starting materials, and the pore forming mechanism of the porous materials with different Si contents was investigated by characterizing the phase constitution, volume expansion rate, pore structure and pore morphology. The results show that the volume expansion, porosity, maximum pore size and permeability of the porous ceramics tended to decrease and then increase with the addition of Si atomic ratio, and the volume expansion, overall porosity, maximum pore size and permeability reached the maximum values of 26.64, 56.21 %, 14.16 µm and 169.48 m3·m−2·kPa−1·h−1 at Si atomic ratio of 1.3, respectively. The phase components with different Si contents were characterized by X-ray diffraction (XRD), and the results showed that the phase constitution gradually changed from MoAlB to MoSi2 as the Si atomic ratio increased. The pore forming mechanism of porous Mo–Al–Si–B was investigated, mainly: interstitial pores generated by the powder pressing process; contraction of the pore structure due to the surface tension of the Al–Si molten liquid phase; and pore forming by the Kirkendall effect caused by the partial diffusion of different solid-state atoms.

Synthesis and structural characterization of gadolinium barium cobalt oxide Gd8Ba5Co4O21 with CoO5 square pyramids

https://doi.org/10.2109/jcersj2.23200

https://doi.org/10.2109/jcersj2.23200

Daisuke Urushihara, Masato Maruyama, Koichiro Fukuda and Toru Asaka

252

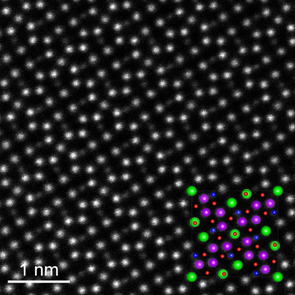

We have determined the crystal structure of Gd8Ba5Co4O21 by single-crystal X-ray diffraction and transmission electron microscopy (TEM). Gd8Ba5Co4O21 shows a tetragonal I4/m structure with a = 13.8982(3) Å and c = 5.76510(10) Å. This compound is isostructural with R8Ba5Ni4O21 (R = rare-earth ions) with two types of BaO10, GdO7 and CoO5 polyhedra. Using scanning TEM, we directly observed the atomic arrangements of Gd8Ba5Co4O21, which was consistent with crystal structure analysis. Isolated CoO5 square pyramids are placed with the relationship to 4-fold symmetry about the c-axis. Gd8Ba5Co4O21 has a similar local structure to R2BaCoO5 with a Y2BaNiO5-type structure. The first neighboring Co–Co atomic distances are shorter than those of R2BaCoO5 because of changes in the framework structure composed of RO7 and CoO5 polyhedra.

◆Announcement◆

Call for a Guest Editor for the Feature

https://doi.org/10.2109/jcersj2.132.A5-1

https://doi.org/10.2109/jcersj2.132.A5-1A5-1

© Copyright by The Ceramic Society of Japan